FLUX Battery Recombination Vent Cap / Plug

FLUX1000……..USD $14.65

FLUX2000…..…USD $18.95

The most advanced Vented Lead Acid Battery vent available today. Reduces watering maintenance to near zero levels. Designed for mission critical battery applications where 100% uptime is not an option. Greatly reduces the threat of environmental Hydrogen emitted in varying quantities from all vented batteries. An absolutely crucial addition to any string of lead acid batteries.

Questions about which FLUX Vent is the correct size, see the SIZE Calculator below.

Converting Hydrogen and Oxygen Battery Gas back into Water….

A truly revolutionary concept now available for a wide variety of lead acid and NiCad batteries. Simply replace any existing battery vent with a Flux Recombination Vent and the results are truly astounding. Reduced maintenance, minimized battery gassing, increased safety enhancements for workers and peace of mind that your batteries are not going dry.

PGM Catalysts are the Key:

Precious Metal Catalysts are the key to achieving hyper efficient gas recombination in our FLUX Recombination Vents. A combination of Platinum Group Metals (PGM) including Platinum Pt, Palladium Pd, Rhodium Rh and others can be used in differing concentrations to stich the Hydrogen and Oxygen emitted by batteries back into an H20 Molecule. This process is typically know as Catalytic Recombination. The resulting recombination process forms a closed loop system whereby ultra clean water is generated using your batteries own original electrolyte.

FLUX Recombination Vents

Advantages:

0 -ZERO Watering on most stand-by / stationary applications

Designed to fit all U.S. and European manufactured batteries including: C&D, Stryten Energy, GNB, Enersys, BAE, Midac and over 50 others.

Life expectancy of 20+ years

Chemistries: Lead Calcium, Lead Selenium, Lead Antimony, Sintered Plate NiCad, Fiber NiCad, Pocket Plate NiCad

From 0 to 4,000 AH.

Polypropylene and heat resistant Valox 325 with a melting temperature of 470-500°F.

Produced in our Ohio and Michigan production facilities. 100% US Made.

Knowledgeable US Based customer support service to answer your questions.

Reduces reliance on ventilation requirements

Mitigates excess explosive Hydrogen emissions

Frees up valuable time spent maintaining multiple battery strings sometimes consisting of thousands of total cells

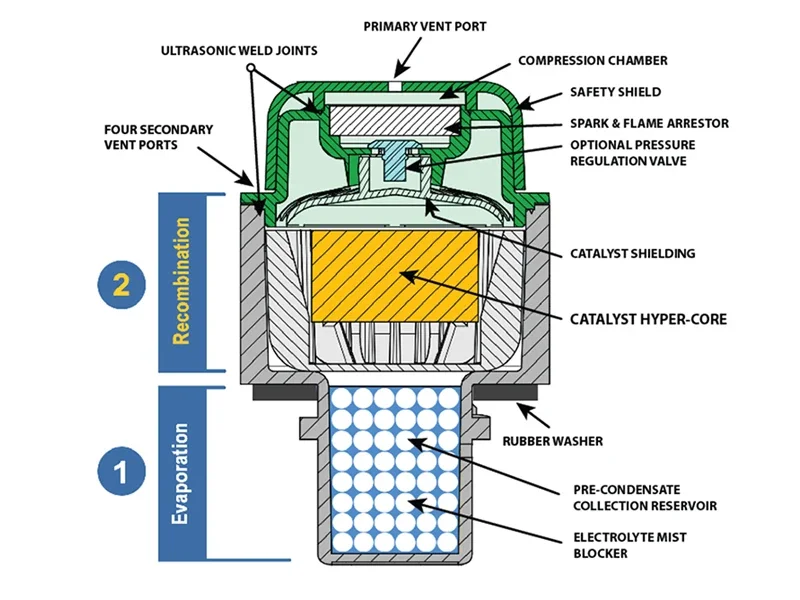

How does Recombination work?

1) Hydrogen and Oxygen Production

As current passes through the battery during a charging cycle, Hydrogen in the form of (H₂) and oxygen (O₂) are produced when water (H₂O) undergoes electrolysis splitting the two molecules apart.

2) Recombination

These gases are then pushed by expanding pressure from inside the cell head into the FLUX Vent. The precious metal catalyst inside the Hypercore then absorb these molecular gases and stitch (recombines) them back together forming water as a by product.

3) Water Returns to Cell

As water is formed, the internal design of the FLUX vent encourages hygroscopic and hydrophobic aggregation of water into larger droplets that are then returned to the battery using a proprietary combination of mechanical and chemical processes.

The catalytic process using a catalyst to facilitate the reaction between hydrogen (H₂) and oxygen (O₂) to form water (H₂O) occurs in multiple steps at the molecular level. If interested, [more on that here]

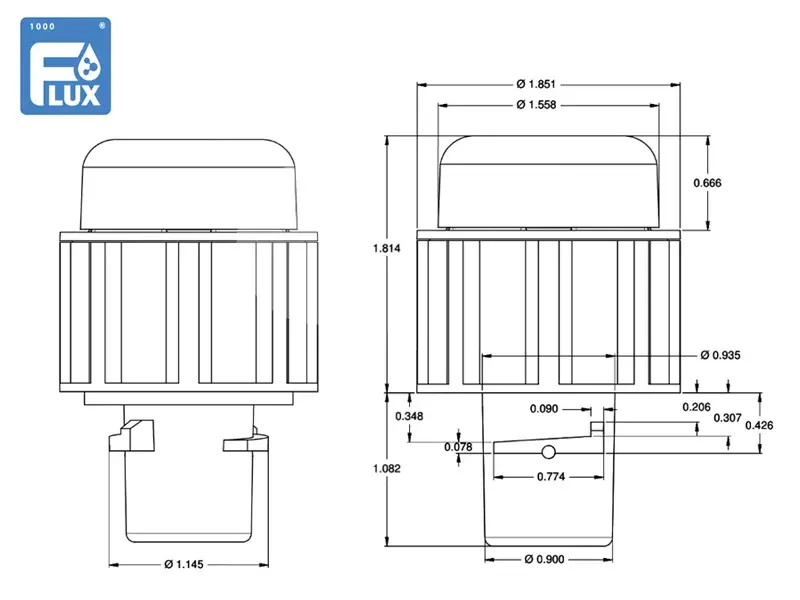

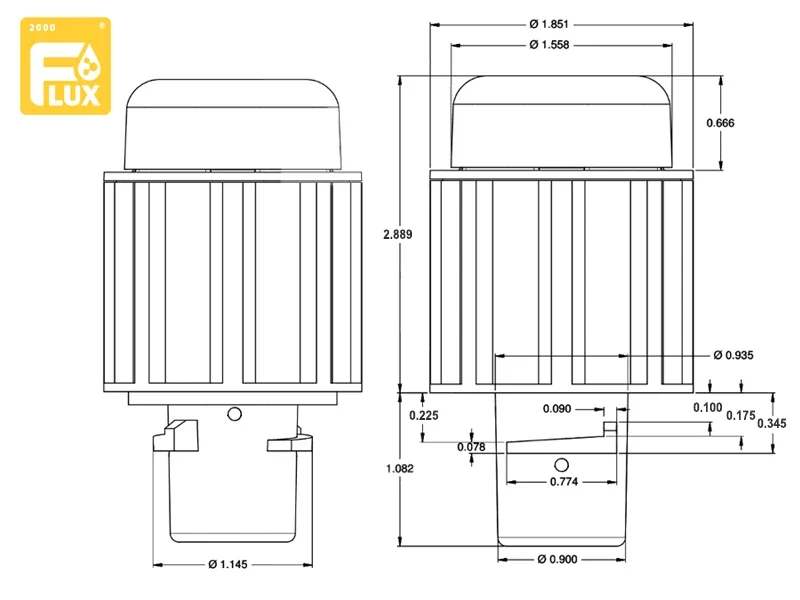

What size do I need, FLUX1000 or FLUX2000?

Sizing is based on (Ah) of the individual cell, not the entire battery. For example, a 3000 (Ah) battery / 2 cells = 1500 Ah per cell. In this case, your battery would require 2 FLUX1000 recombination vents. Most batteries will use the FLUX1000. There are only a handful of very large capacity batteries that will utilize the FLUX2000.

FLUX1000 = 0 to 2,000 (Ah) / Per Cell , FLUX2000 = 2000 to 4,000 (Ah) / Per Cell

Compatible Batteries…

EverExceed

SBS / Exponential Power

Tab

Duncan

Alcad

Midac Technologies

Energia Integral Andina

Eternity Technologies

Hoppecke

Luminous Technologies

Fiamm

Exide

Gold Light Power

JYC Battery

LEOCH

CS Battery

Eagle Eye Power Solutions

King Power

Bater

Microtex

Vela

Exor Battery

Sunlight

KIJO

GA Cell

Champion Battery

Sail Solar

MAK Power

MHB Battery

and many others…

SURESEAL™ Washer System

How can we accommodate so many different types of batteries? Our SureSeal™ Washer System allows us to fit the FLUX Vent to just about any Stationary or Standby battery globally. By increasing or decreasing the thickness of our EPDM Rubber washer, we can accomodate batteries from almost all manufacturers.

90% of all batteries of this type use an industry standard bayonet style to lock the vent cap into the battery.

For battery systems using non-standard vent attachments, such as smaller / larger cell openings, threaded cells (e.g., GNB), or push-fit style, Flow Systems offers a comprehensive suite of precision-molded adapter fittings. These accessories enable seamless FLUX Vent integration across a wide range of geometries and configurations, ensuring consistent sealing performance and operational integrity. [ more… ]

If you don’t see the manufacturer of your batteries listed above or are still unsure about sizing the FLUX Vent to fit your battery, contact us at +01 (419) 290-1103 or contact us by email for sizing and compatibility questions. We can review technical drawings or actual battery cell covers to determine which configuration best suits your needs. Chances are we have a recombination solution that will work with your system.

Questions & Answers…

Call us at 1 (419) 290-1103

-

By default, the FLUX Vent does not come with a bi-directional valve. These can be installed upon request.

WHAT FUNCTION DOES A BI-DIRECTIONAL VALVE SERVE?:

When installed, a bi-directional valve will act to increase gas recombination efficiency by concentrating the escaping hydrogen and oxygen in the immediate vicinity of the catalyst core.% INCREASE IN EFFICIENCY

During testing it was found that having a valve installed increases the recombination efficiency by only 1% to 2%. Considering the existing efficiency at which FLUX Vents already operate, a bi-directional valve is not imperative to its operation and does not incrementally add to its overall performance.CONSIDERATIONS WHEN USING A BI-DIRECTIONAL VALVE

With the valve installed, the resulting pressure in the headspace of the battery is increased.

If your battery uses a sample tube, the increased head pressure may push electrolyte up and out of the sample tube.

-

While you can order as many or few Recombination Vents as needed, the standard case size is 60 pieces which best matches the typical string size for most industrial power and utility companies.

SMALL CASE = 24 PIECES

STANDARD CASE = 60 PIECES

LARGE CASE = 120 PIECES

XLARGE CASE = 144 PIECES

-

FLUX RECOMBINATIN VENTS

We do not currently have a minimum order quantity for FLUX Vents at this time.

HYDROMAX CATALYST

The minimum order quantity for any HMAX Hydromax formulation is 10g. The 10g sample is enough catalyst to recombine 14 l/min of gas if used at one time. Also sold by the Kg. -

All Flow Systems products are 100% unconditionally guaranteed for the period of 1 year from date of purchase. We will accept all returns or exchanges regardless of condition due to defects in workmanship. Proof of purchase must be supplied at the time of return or exchange.