FREE Flux Battery Recombination Vent Testing Program…..Learn More

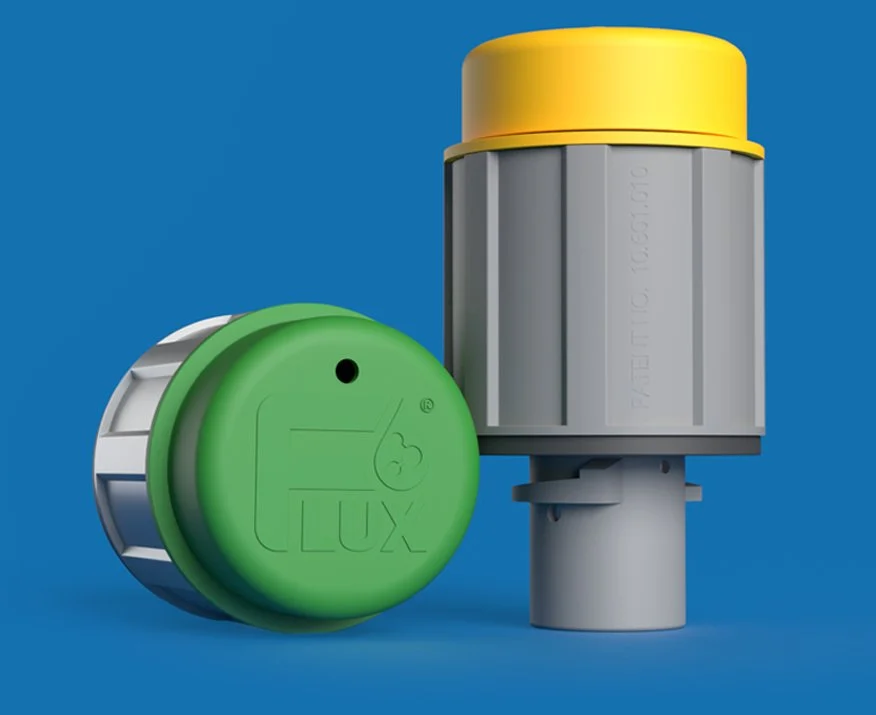

Simply put, FLUX Recombination Safety Vents reduce stationary battery watering maintenance by 20x, reduce dangerous environmental hydrogen, reduce ventilation requirements all while substantially increasing worker safety.

Call us with questions at (419) 290-1103. Full technical support - 24 hours

WHEN EVERY DROP COUNTS

Who uses Recombination Battery Vents?

Who uses Recombination Battery Vents? Any VLA (Vented Lead Acid) battery backup system that currently has standard issue ceramic spark arresting vent caps is a perfect candidate for replacement with the FLUX Safety Recombination Vent.

There are now thousands of vents deployed in critical power and backup facilities throughout the U.S. and abroad.

Ideally suited for the very smallest battery bank to largest substation battery racks.

Industrial Power & Utilities

Renewable Energy

Data Backup / UPS

Telecommunications

Security Centers

Emergency Lighting

Medical Facilities

Defense Installations

Refineries

Drilling & Mining

Locomotive / Railway

Air Traffic Control Centers

Near (0) Zero Watering

Triple Redundant Gas Venting

Spark and Flame Arrestor

One Piece, Ultra-Sonic Welded Construction

Hygroscopic + Hydroscopic + Condensation

2 Stage Patented Recombination Process

Highest Hydrogen Escape Path

Reduces Micro-particulate gaseous forms of (H2S) Hydrogen Sulfide, Arsine, Stibine and Amines.

Fits all stationary VLA batteries (more…)

Ultra-low Profile

Rapid Water Recovery Process

Superior Performance, Superior Design…

We’ve spent the past 50 years developing vent caps for just about every battery manufacturer around the world. In that time, we’ve learned a thing or two about how to incorporate safety with performance. The FLUX Recombination Vent is the culmination of all our proprietary knowledge resulting in the most advanced lead-acid battery vent available today.

Converts Hydrogen and Oxygen Battery Gas back into Water….

A truly revolutionary concept now available for a wide variety of lead acid and NiCad batteries. Simply replace any existing battery vent with a Flux Recombination Vent and the results are truly astounding.

Key Advantages:

Reduced Maintenance

Increased Safety

0 -ZERO Watering on most stand-by / stationary applications

Designed to fit all U.S. and European manufactured batteries including:

C&D, Stryten Energy, GNB, Enersys, BAE, Midac and over 50 others.Life expectancy of 20+ years

Chemistries: Lead Calcium, Lead Selenium, Lead Antimony, Sintered Plate NiCad, Fiber NiCad, Pocket Plate NiCad

Intentional Design based on years of Experience….

While the development of the FLUX Recombination Vent started in 2018 we are constantly improving the design and efficiency aspects of the FLUX Vent. Our production philosophy is constant evaluation and improvement.

2025 Version 99X102 Tech Updates:

Internal mechanics of drainage system enhanced

Sonic Welding micro-alignments

Addition of 2 further hydrogen escape paths

Fortified joint stabilization

Evaluation and selection of rubber washer durometers

Primary cap vent hole repositioned